+

—

Leak Detection Services

+

—

Waterproofing works

+

—

Civil works

LIFT PIT WATERPROOFING

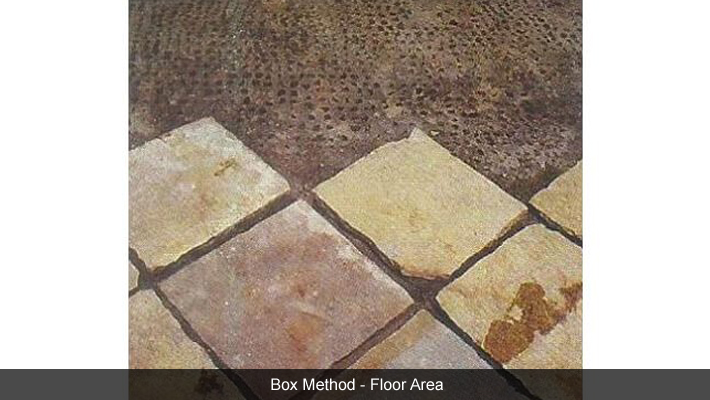

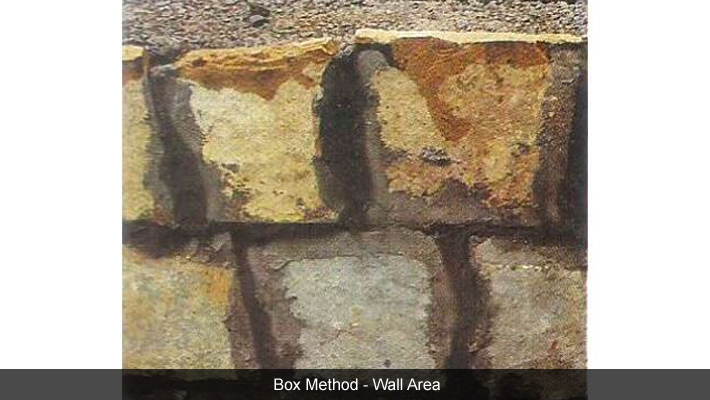

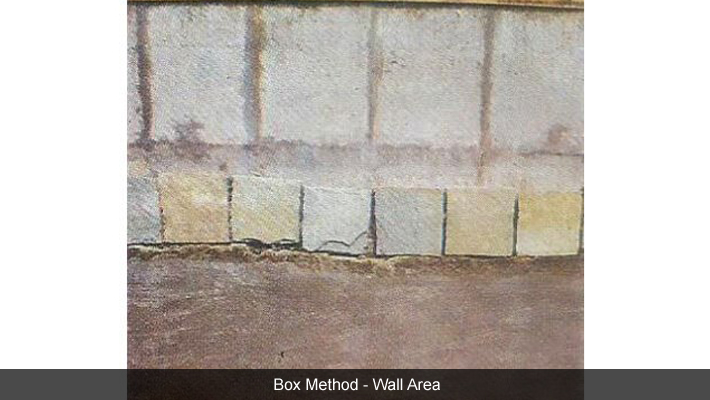

BOX METHOD

We propose to treat the UG Structure by our Box Method. For this we would require 150mm (6’’) thick layer of cement concrete (1:3.6) P.C.C. using metal upto No. 2 laid even with smooth surface with wooden trowels by the owners on well compacted soil or rubble soiling or plain concrete. The bottom P.C.C. should be laid in such way that it shall project minimum 6’’ (150mm) beyond the face of bottom P.C.C. Raft on all sides. On the P.C.C. we shall provide waterproof layer C.M. of 1” thick on which stone aggregate of nominal size will be embedded at random. We shall provide Shahabad rough ladi (stone) of about 1 to 2 feet square and of 20 to 25 mm thick fixed in C.M. (1:4) above the ladi we shall again provide waterproof layer of ½” to ¾” thick. Like this the total thickness of our treatment becomes 3” thick. This is then super imposed by the owner with R.C.C. Raft. After Casting of R.C.C. Raft and side walls by the owners, the outerface of the walls are provided with our Shahabad ladi and then grouted with the waterproof cement slurry, above the ladi we shall provide ½” to ¾” thick waterproof layer, like wise out treatment becomes of about one foot above ground level. The excavated portion of the sides around is then or simultaneously with our work is filled in by the owners with soft earth. By this method the entire structure is encased by our treatment and the attacking subsoil water will not find an access to it.

INJECTION & SURFACE METHOD

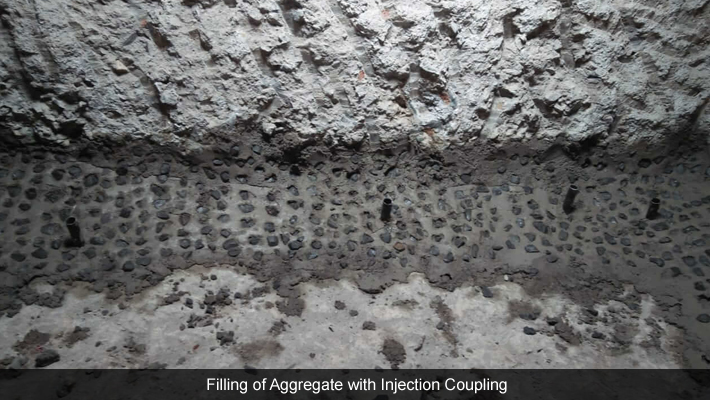

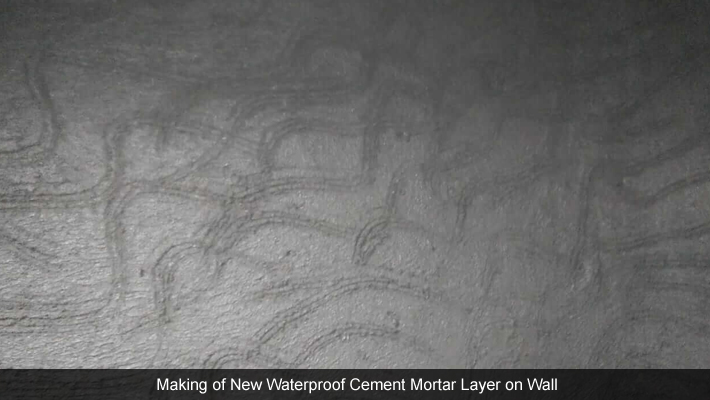

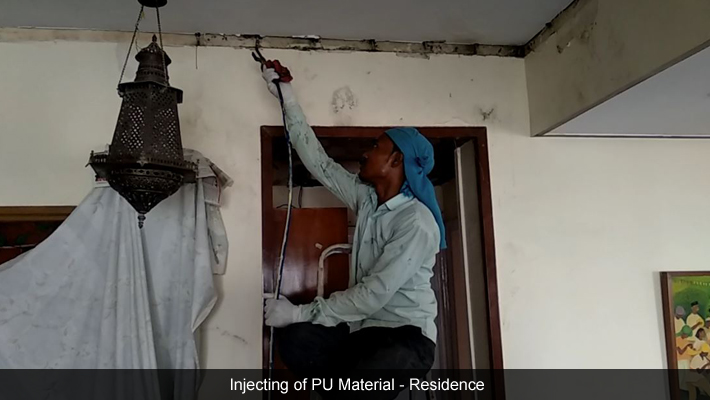

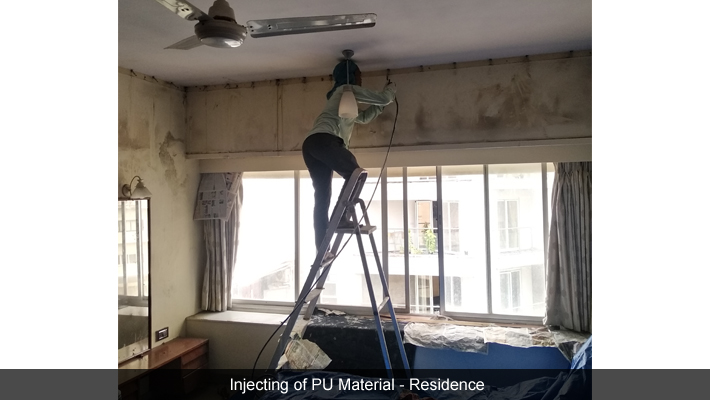

In case of existing Liftpit / UG structure where no access is available for treating the structure from outside and below. We propose to treat the UG structure by injection & surface method. The junction of the bottom raft with the vertical wall is to be opened by us and filled with metal aggregate of nominal size along with injection (coupling). In the wall area of construction joints are opened to provide injections. Injections shall be provided as and where found necessary by us as per site conditions. The injections are filled with waterproof cement slurry (grouting). After the injections are finished with cement grouting, we shall provide a layer of I.P.S. of about 2” thick on the floor and vertical wall is covered with waterproof layer of about 1” thick. Like this the structure is waterproofed from inside.

Note: the final surface of the floor will be finished smooth in cement color and that of the walls with cement / neeru finish. If however, it is desired to provide tiling over our treatment then the surface of our treatment will be finished in a manner to receive the tiles. It may please be noted that our treatment should in no manner be punctured or damaged. If any fixtures are necessary, then they will be provided over our treatment so that our treatment is not damaged or tampered with. In case the floor of the Liftpit is to be subjected to rough and/or heavy use then a suitable wearing coat on our surface shall be necessary to be provided by the owners. In case any existing treatment is present, the same shall be removed by us to expose the surface of RCC raft.

CRYSTALLINE METHOD

The treatment mainly depends upon the procedure & specification provided by the architect / owner. Treatment for horizontal & vertical construction joints & crack filling for raft and retaining wall shall consist of opening of construction joints 35mm x 35mm width and depth respectively, cleaning it with jet spray, after which there will be an application of super strong mortar, high strength, quick setting and polymer reinforced repair mortar for construction joint treatment. After which providing & laying of non-shrink cementitious grout in Liftpit floor and wall area shall be carried out for filling the porosity and capillaries of the structure. PU resin and foamy injections may be injected if at all any active water leakage found during the treatment or for filling the honeycombing in the structure. Lastly applying alkaline cement based crystalline waterproofing system in three coats to the Liftpit raft and retaining wall area. This becomes an integral part of the concrete through crystallization process which seals all cracks and voids, above this a protective coating plaster has to be provided. Note: Opening of tie rods shall be done by the owner. After which application of super strong mortar, high strength, quick setting and polymer reinforced repair mortar for waterproofing treatment to tie rods may needed to be done.

UNIVERSAL WORKS WATERPROOFING WARRANTY

UNIVERSAL WORKS WATERPROOFING WARRANTY

INJECTION & SURFACE METHOD

CRYSTALLINE METHOD

The treatment mainly depends upon the procedure & specification provided by the architect / owner. Treatment for horizontal & vertical construction joints & crack filling for raft and retaining wall shall consist of opening of construction joints 35mm x 35mm width and depth respectively, cleaning it with jet spray, after which there will be an application of super strong mortar, high strength, quick setting and polymer reinforced repair mortar for construction joint treatment. After which providing & laying of non-shrink cementitious grout in Liftpit floor and wall area shall be carried out for filling the porosity and capillaries of the structure. PU resin and foamy injections may be injected if at all any active water leakage found during the treatment or for filling the honeycombing in the structure. Lastly applying alkaline cement based crystalline waterproofing system in three coats to the Liftpit raft and retaining wall area. This becomes an integral part of the concrete through crystallization process which seals all cracks and voids, above this a protective coating plaster has to be provided. Note: Opening of tie rods shall be done by the owner. After which application of super strong mortar, high strength, quick setting and polymer reinforced repair mortar for waterproofing treatment to tie rods may needed to be done.

All work completed by Universal Waterproofing Works carries a warranty of 10 years. Your Universal Waterproofing Works signed contract is your actual Warranty Certificate.

Universal Waterproofing Works warrants all materials and workmanship only pursuant to the job description details on your written contract, provided the home owner / society / builder / client has made full and final payment.

WARRANTY PERIOD : 1 / 3 / 5 / 7 / 10 YEARS (As applicable)

Universal Waterproofing Works warrants all materials and workmanship only pursuant to the job description details on your written contract, provided the home owner / society / builder / client has made full and final payment.

WARRANTY PERIOD : 1 / 3 / 5 / 7 / 10 YEARS (As applicable)